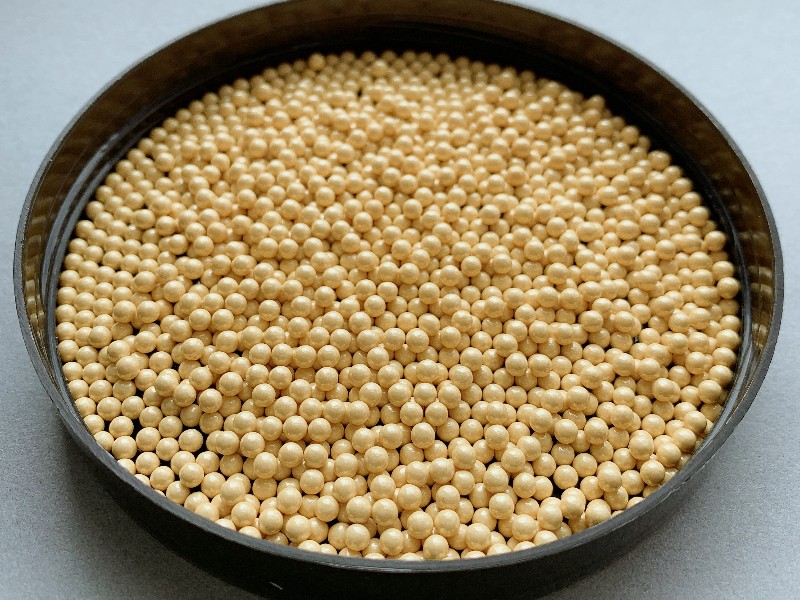

Property

1.Wide application scope,especially for materials with high hardness and viscosity.

2.Large Specific density which maintains high grinding kinetic energy and improves grinding efficiency.

3.Smooth surface, easy to clean and wear less to equipment.

4.High mechanical strength, impact resistance, high speed operation without fragmentation.

5.Good wear resistance:25-45 times more than glass bead, 5 times more than zirconium silicate beads.

6.High grinding efficiency :6-8 times more than glass bead, 2-3 times more than zirconium silicate beads.

7.Easy to Clean & Store

8.High Resistance To Wear & Tear

9.Corrosion Resistant

Recommendations For Grinding Applications

Wear-resistant .corrosion-resistant products: paper making ,coating ,textile ,pigment and dye.

High strength, high toughness products : magnetic materials, piezoelectric ceramics ,dielectric ceramics.

Ceramics: electric ceramics,refractory ceramics ,structural ceramics.

Medicine ,food ,cosmetics.

Technical Specification

|

Items

|

Specification

|

|

Chemical Composition

|

83-87% ZrO2

9-13% CeO2

<2.0% Others

|

|

Bulk Density

|

≥3.75g/cm3

|

|

Density

|

>6.0g/cm

|

|

Compressive strength

|

>1.5KN (Φ2mm)

|

|

Vickers hardness

|

>1150

|

|

Self consumption (ppm/h)

|

<0.8

|

|

Roundness

|

≥0.97(Xmin/Xmax)

|

Available Size

|

Size(mm)

|

|

0.4-0.6

|

0.6-0.8

|

0.8-1.0

|

1.2-1.4

|

1.4-1.6

|

|

1.6-1.8

|

1.8-2.0

|

2.0-2.2

|

2.2-2.5

|

2.5-2.8

|

|

2.8-3.2

|

3.2-3.5

|

4

|

5

|

6

|

|

Remark: can be cuslomized for clients

|

Calculation Method

M=3.14×R2×D×L×(25%-50%)÷1000

M: Total quantity of ceramic ball

D: Density (g/cm3)

R: Radius of the mill (cm)

L: Length of the mill (cm)

Package

20kgs or 25 kgs/plastic drum

Common Problem

1.WhatAreCeriaStabilizedZirconiaBeads?

Ceria stabilized zirconia beads is a type of zirconia beads used for grinding, milling, and dispersion process.

High strength and high fracture toughness are two important properties of these media balls.

It consists of 85 percent zirconia (ZrO2) and 15 percent cerium dioxide (CeO2).

You can use this media in normal horizontal bead mills as well as in other milling machines also

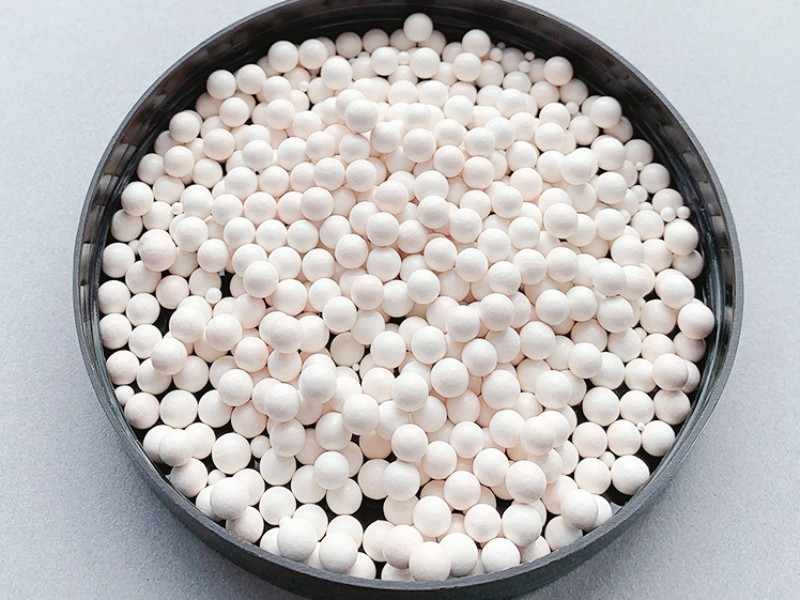

2. What Are The Advantages Of Using Ceria Stabilized Zirconia Beads?

The benefits of using Ceria Stabilized Zirconia Media are listed below.

2.1 High Media Life

The ceria stabilized zirconia beads come with very high life.

Their life is higher than glass beads and magnesia stabilized zirconia beads.

This high media life makes it very attractive to the customers.

2.2 High Grinding Efficiency

The high-density feature of these media balls helps to increase the grinding efficiency.

Thus, you can grind more materials in less amount of time.

2.3 High Chemical Resistance

Their high chemical resistance makes it possible to use many types of chemicals in the slurry.

The media is unaffected by the usage of these chemicals.

No harm happens to the ceria stabilized zirconia beads with the chemical use.