· Zirconia

· Yttria

· Alumina

· Cerous oxide

ZrO2

Y2O3

Al2O3

CeO2

· Zirconia

· Yttria

· Alumina

· Cerous oxide

ZrO2

Y2O3

Al2O3

CeO2

The reserves of Zr in the earth's crust are 0.025%, exceeding the reserves of metals such as Cu, Zn, Sn, Ni, and Pb, and the resources are abundant.

rich. In nature, Zr appears in the form of zircon, baddeleyite and their variants.

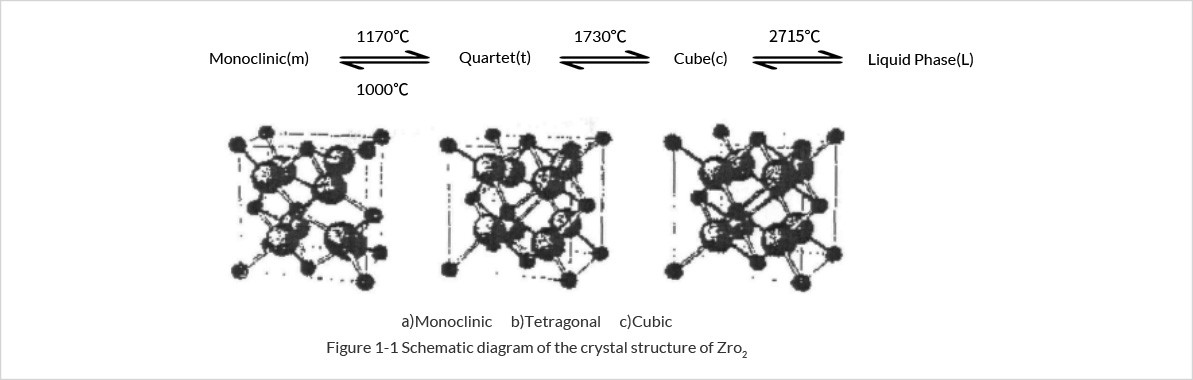

High-purity Zr02 is white powder, yellow or gray when it contains impurities, generally contains HfO2, not easy to separate, melting point 2715°C. At different temperatures, ZrO2 mainly exists in three isomorphic forms, namely monoclinic (m-Zro2).

The tetragonal crystal system (t-ZrO2) and the cubic crystal system (c-ZrO2), the schematic diagram of the crystal structure is shown in Figure 1-1.

The chemical compositions of the three structures of Zr02 are basically the same, and their existing forms are related to temperature and pressure, At normal pressure, the relationship among the three forms can be expressed as:

However, when appropriate stabilizers, such as Y2O3, Mgo, CaO, CeO2, etc. are added to ZrO2 ceramics, the cubic phase (c)--tetragonal phase (t) and tetragonal phase (t)--monoclinic phase (m) can be reduced. The phase transition temperature enables the high temperature stable cubic and tetragonal phases to be stable or metastable at room temperature. When enough stabilizer is added, the cubic phase stable at high temperature can be maintained until room temperature without phase transition.

Y-TZP:Yttria Stabilized Zirconia Bead

CZ:Ceria Stabilized Zirconia Bead

The true density is that the object is dried to a constant weight under the specified conditions (105 degrees plus or minus 5 degrees, and the temperature is 20 degree plus or minus 2 degrees), the mass per unit true volume (the volume of the mineral entity without pores)

ρ=m/v

Detection method: According to Archimedes' law, the real volume of the object is measured by the drainage method.

| Materials | YTZP bead | Alumina ball | Midalumina ball | ZTA ball | ATZ ball | Zirconium Silicate bead | Glass bead |

| Density g/cm3 | 6.0±0.1 | =3.6 | -2.9 | =4.1 | =5.2 | 4.2~4.5 | 2.4~2.8 |

In the natural state of accumulation, the bulk volume of the material includes the internal pores of the material and the loose material particles mass per unit volume of pores between

ρ=m/V

Heap specific gravity detection

Detection equipment: 100ml volumetric flask, electronic balance

Detection method:

a. Pour the detected ball into a 100ml volumetric flask, and pour it on the scale accurately.

b. Weighing G

c. Calculation formula:

Bulk specific gravity D=G/100

Bulk Specific Gravity of Grinding Media for Various Materials

| Materials | YTZP bead | Alumina ball | Midalumina ball | ZTA ball | ATZ ball | Zirconium Silicate bead | Glass bead |

| Density g/cm3 | 3.3~3.8 | 2~2.2 | 1.6~1.8 | 2.1~2.8 | 2.6~3.3 | 2.2~2.5 | 1.5~1.7 |

Formula: W=P*D*L

P---Filling rate

D---Heap specific gravity

L---Effective use volume

Hardness indicates the ability of a material to resist the pressing of a hard object into its surface. it is metal

One of the important performance indicators. Generally speaking, the higher the hardness, the better the wear resistance. commonly used hardness

The indicators are Brinell hardness (HB), Rockwell hardness (HR), Mohs hardness and Vickers hardness (HV).

Strength is the ability of a material to resist damage. But often under different stress conditions, the strength exhibited by the material is different. Under compressive stress, resistance to damage. is the compressive strength.

When the material sample is under pressure, the maximum stress that it will bear before crushing Unit: MPa or N/mm2

The water absorption rate is the percentage of the water absorbed by the pores in the ceramic product.

Porosity is the percentage of pores in a ceramic article that account for the total volume of the article.

A.Sieve

The operation of classifying solid particles into several levels by size is called classification, using

The grading of a screen surface with a certain size of aperture is called sieving.

B.Mesh

Chinese standard sieve adopts metric sieve size

The sieve size is expressed by the number of sieve holes per square centimeter area, and the sieve number is expressed by the number of sieve holes on one centimeter of length

Imperial sieve number

The number of holes n per inch of length

The number of meshes counted in a row on a given unit length in succession.

Note: The number of meshes with a length of 25.4mm, that is, marked "mesh".

1 inch = 25.4mm

Amount of loss per unit time of grinding media during use

Testing equipment: fast mill, 1L ball mill, slow mill, 4L ball mill, electronic balance

Detection method: 1) Rapid grinding (aluminum powder)

1) Rapid grinding (aluminum powder)

a. Use an electronic balance to weigh about 800 grams of ball G1, 100 grams of alumina powder, 380 grams of water

Put it into a 1L ball mill jar and quickly grind it for 6 hours

b. Cleaning, drying and weighing G2.

Calculation formula:

Wear W=(G1-G2)/G1*100%

2) Slow grinding,

a. Use an electronic balance to weigh about 2500 grams of the ball and weigh G1, put 2500 grams of water into a 4L ball mill, and mill it for 60 hours.

b. Cleaning, drying and weighing G2.

Calculation formula:

Wear W=(G1-G2)/G1*100%

Wear is mainly divided into four basic types according to different mechanisms and conditions:

①Adhesive wear, the main feature is that there are fine scratches on the wear surface, and material transfer phenomenon occurs in severe cases, and the wear products are mostly flakes or small particles;

②Abrasive wear, the main feature is that there are obvious scratches or furrows on the wear surface, and the wear objects are strips or cuttings;

③Fatigue wear, the main feature is that there are cracks, small pits, etc. on the wear surface, and the wear products are block or cake;

④Corrosion wear, the main feature is that there are chemical reaction films or small pits on the worn surface, but the pits are relatively smooth.

The powder sample is divided into several grades according to different particle sizes, and the percentage of each grade of powder (by mass, quantity or volume). Particle size distribution: Use specific instruments and methods to reflect the percentage of particles with different particle sizes in the total particle size in the powder sample [1]. There are two forms of interval distribution and cumulative distribution. Interval distribution, also known as differential distribution or frequency distribution, represents the percentage of particles in a range of particle size intervals. The cumulative distribution is also called the integral distribution, which indicates the percentage of particles smaller or larger than a certain size. Several key indicators of particle size characteristics: ① D50: The particle size corresponding to the cumulative particle size distribution percentage of a sample reaching 50%. Its physical meaning is that the particles with a particle size larger than it account for 50%, and the particles smaller than it also account for 50%. D50 is also called the median diameter or median particle size. D50 is often used to represent the average particle size of powders. ② D97: The particle size corresponding to the cumulative particle size distribution number of a sample reaching 97%. Its physical meaning is that particles with a particle size smaller than it account for 97%. D97 is often used to indicate the particle size index of the thick end of the powder. The definitions and physical meanings of other parameters such as D16 and D90 are similar to those of D97.

It is the abbreviation of BET specific surface area detection method, which is named because it is based on the famous BET theory. BET is the acronym of the three scientists (Brunauer, Emmett and Teller). Based on the multi-molecular layer adsorption formula derived by the three scientists from classical statistical theory, the famous BET equation has become the theoretical basis of particle surface adsorption science. , and is widely used in the study of particle surface adsorption performance and data processing of related detection instruments. Specific surface area refers to the sum of the total external surface area of all particles in each gram of substance, the international unit is: m2/g, the specific surface area is an important parameter to measure the properties of the substance, which can be detected by special instruments, usually such instruments need to be based on BET theory. perform data processing