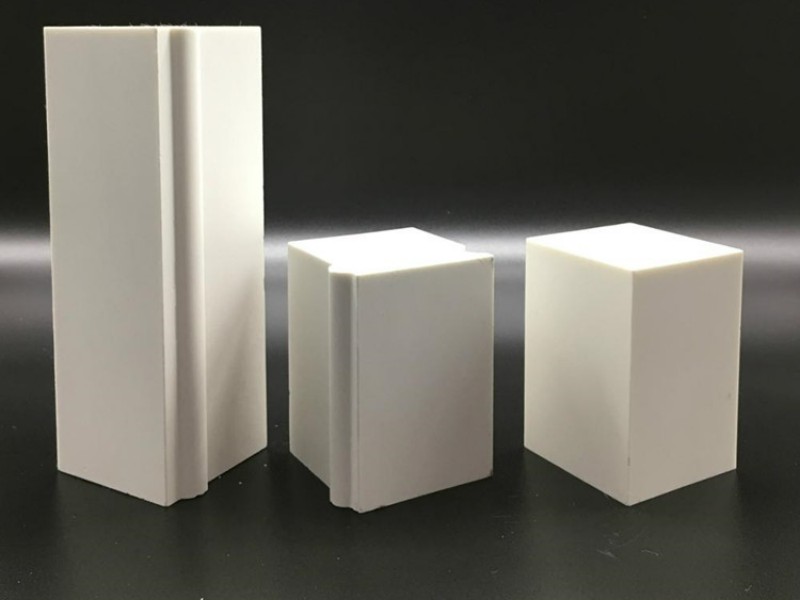

Aluminum oxide beads are a high-hardness grinding medium made from alumina (Al2O3). These beads exhibit high wear resistance and impact resistance, making them perform well in high-load grinding environments. The hardness of aluminum oxide beads is second only to diamond. They do not chemically react with the materials being ground, thus not introducing any contamination during the grinding process. Aluminum oxide beads have a long service life and low maintenance costs, and they also possess good thermal stability, able to withstand high temperatures without melting or deforming.