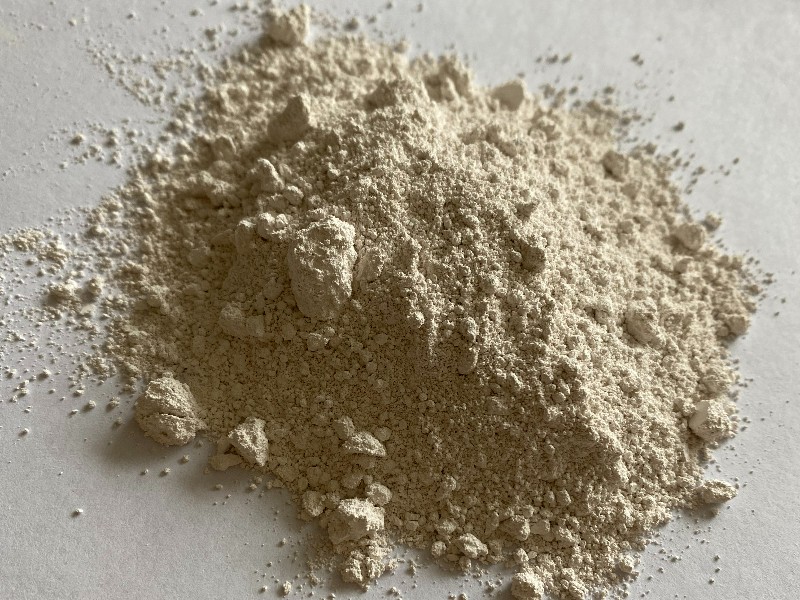

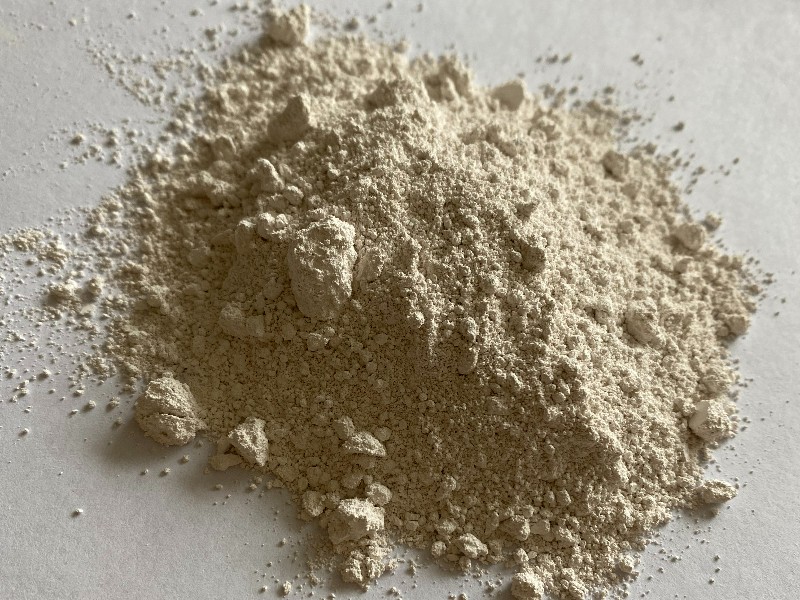

High refractive index of 1.93-2.01, chemical stability, is a high-quality, inexpensive opacifier, widely used in the production of various architectural ceramics, sanitary ceramics, household ceramics, first-class handicraft ceramics, etc.

High refractive index of 1.93-2.01, chemical stability, is a high-quality, inexpensive opacifier, widely used in the production of various architectural ceramics, sanitary ceramics, household ceramics, first-class handicraft ceramics, etc.

1.It has good chemical stability and is not affected by the atmosphere of ceramic sintering, which can significantly improve the bonding performance of ceramic glaze and improve the hardness of ceramic glaze.

2.Whitening effect: The whitening effect of zirconium silicate powder is due to the formation of baddeleyite zircon after the ceramic is fired, thereby forming a whitening effect on the incident light wave.

Used in glass additives, sanitary ware, wall and floor tiles and other ceramic glazes, fine particle size, reasonable distribution, high whiteness, low reflection performance, strong hiding power, good dispersion in various ceramic glazes, good opacity, Good liquidity.

|

Item |

Chemical component(%) |

μm(D50) |

Degree of whiteness (1200℃*10min)% |

Burning loss 1g. Loss H2O Containing)% |

||

| ZrO2 | Fe2O3 | TiO2 | ||||

|

ZL-S060 |

≥60 | ≤0.25 | ≤0.25 |

0.8±0.1 |

≥90 | ≤0.8 |

|

ZL-S063 |

≥63 | ≤0.1 | ≤0.2 |

0.8±0.1 |

≥93 | ≤0.8 |

|

ZL-S064 |

≥64 | ≤0.1 | ≤0.2 |

0.8±0.1 |

≥95 | ≤0.8 |

Is packaged by 25kgs / drum.It can be used for a long time, if it is avoided directly to contact with moist environment